Problems happen

In manufacturing, problems that happen may be due to human error, machinery failure, lack of maintenance, or any number of issues. Correcting the problem may or may not be an easy fix.

More importantly, identifying the root cause of the problem, the factor that was the main cause of it, will likely prevent it from happening again.

Root Cause Analysis

This is when it may be beneficial to conduct a Root Cause Analysis (RCA) – an analytical, systematic approach to define, identify, and solve a problem by seeking out the origin of it. RCA can also be used to modify core process and system issues in a way that prevents future problems.

Magnifying GlassThe goals of conducting a Root Cause Analysis are to:

1) Discover the root cause of the problem

2) Understand how to fix, mitigate, or learn from any underlying issues within the root cause

3) Apply what is learned during the process to systematically prevent future issues

Treating individual symptoms may seem productive and solving many problems may appear as if something is getting done. In reality, if you don’t diagnose the real root of a problem, you’ll most likely have to deal with the same problem again and again.

Core Principles

There are core principles that guide an effective Root Cause Analysis process to help gain trust and buy-in from key stakeholders in an organization. They include:

- Focusing on correcting the root cause rather than just symptoms

- Knowing the importance of treating symptoms for immediate relief

- Realizing there may be multiple root causes to a problem

- Focusing on how and why the problem occurred, not who was responsible

- Determining cause and effect evidence to inform a corrective course of action

- Thinking about how the root cause can be prevented in the future

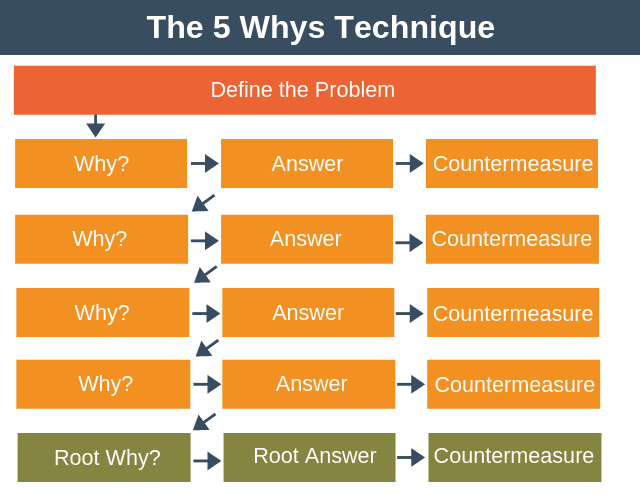

5 Why’s

There are a number of different strategies and techniques that can be used for root cause analysis. One of the most common and widely used approaches is called the “5 Why’s” approach, a continuous improvement technique used to reveal an issue’s root cause.

Just asking “why” once is usually not enough to get to the heart of the root cause and create a permanent working solution. Experience suggests that about five “why” questions will generally delve deep enough to lead to most root causes but sometimes more or less are required depending on the issue.

The point is that asking the question several times over may be necessary to get to the true root cause of what’s causing the problem.

Manufacturing Example

Here’s a manufacturing example, using the 5 Why’s for Root Cause Analysis, from Taiichi Ohno, creator of the 5 Why’s technique:

1) Why did the robot stop working? “The circuit overloaded, causing a fuse to blow.”

2) Why is the circuit overloaded? “There was a lack of lubrication on the bearings, so they locked up.”

3) Why was there insufficient lubrication on the bearings? “The oil pump on the robot is not circulating sufficient oil.”

4) Why is the pump not circulating sufficient oil? “The pump intake is clogged with metal shavings.”

5) Why is the intake clogged with metal shavings? “Because there is no filter on the pump.”

We discover a root cause to this problem is no filter on the pump.

In this case, the 5 Why’s serve as a method to avoid assumptions. Each incremental question provides more detailed answers which become clearer and more concise each time. Ideally, asking the last “Why” question will lead to identifying a process or event that failed which can then be fixed and avoid happening again.

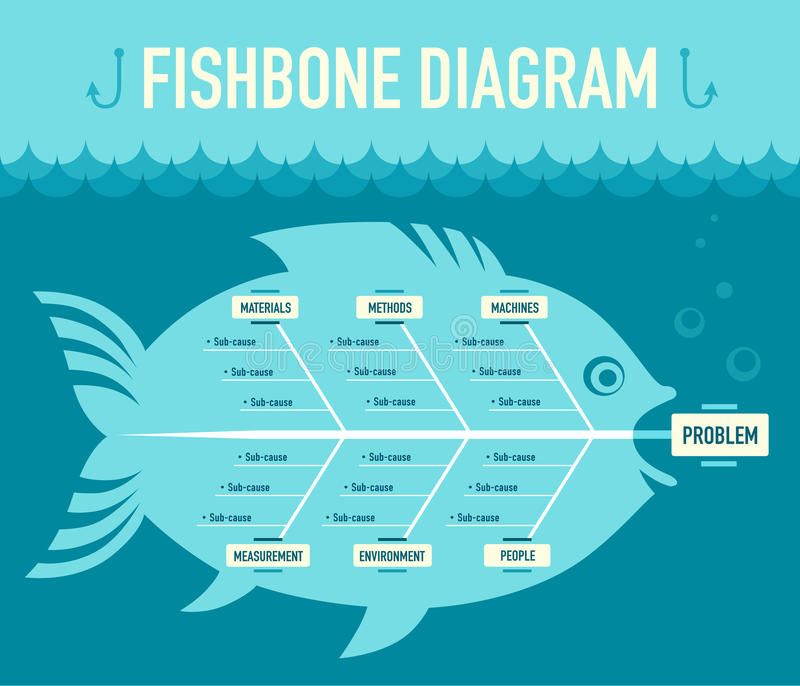

This is just one Root Cause Analysis tool or technique. Another common technique is a fishbone diagram which is a cause and effect diagram designed to track down imperfections, defects, or failures. It looks like a fish skeleton with the problem at its head and the cause for the problem spreading into the spine.

Other tools associated with RCA include Pareto charts, failure mode and effects analysis (FMEA) and Kaizen, to name a few.

Root Cause Analysis is a smart tool for figuring out where something went wrong. While it’s typically used as a way to diagnose problems, it can be equally effective determining the root cause of a success.

It’s not a bad idea to find out the root cause of why things are going well. This kind of analysis can help prioritize and protect factors in a process and may translate success in one area of your business to success in another area.

Related Items

Often basic housekeeping is overlooked in favor of “productivity.” This is a common practice but one that costs you over the long run. Putting a basic 5S program in place is inexpensive and yields a great return on your (small) investment.

The company tasked itself to grow the business with current resources by becoming more efficient, reducing waste, and developing more productive internal capabilities.

This course provides comprehensive exposure to the principles and practices needed to develop and sustain a Lean Enterprise. You will receive immediate reinforcement of the classroom learning by applying your training to a real-life project within your organization.